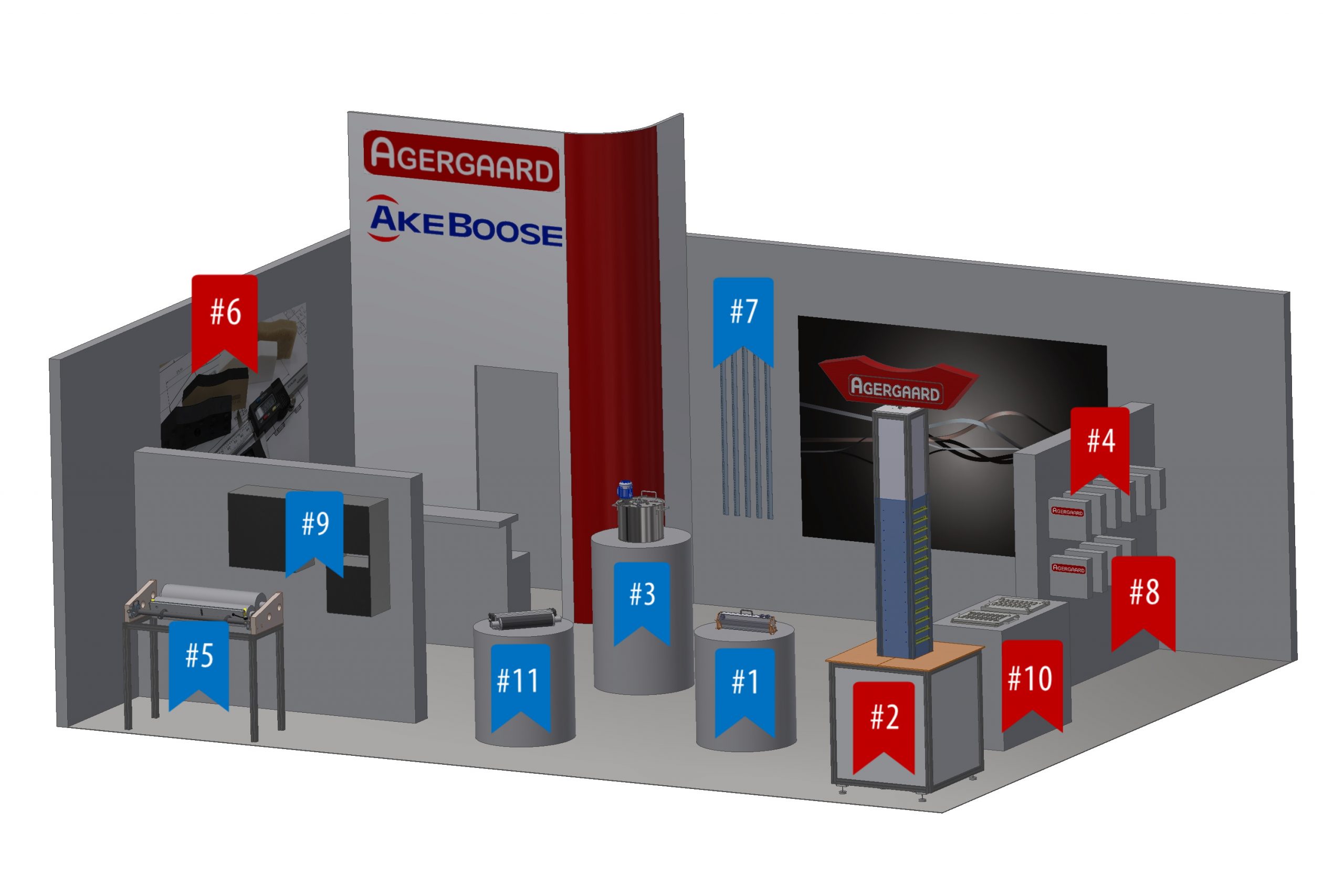

Sala de exposición virtual de AkeBoose

La drupa 2020 se ha reprogramado para el año que viene, pero seguiremos teniendo una versión online de la exposición.

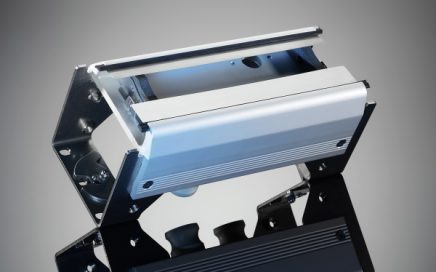

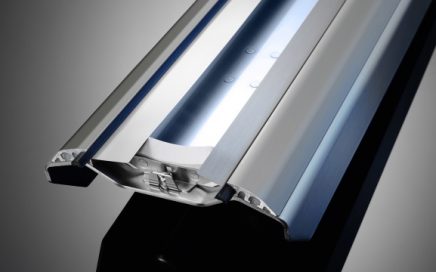

Día 11 - 26 de junio de 2020 - Sistema de cámara de entintado NOVA Compact

Transferencia de tinta rentable y precisa

NOVA Compact es un sistema de cámara cerrada compacto que ofrece una excelente transferencia de tinta y rendimiento de rascado. Basado en un perfil de aluminio anodizado, su delgado diseño puede adaptarse a diámetros de rodillos anilox que van de 70 a 150 mm. Hasta una anchura de impresión de 1000 mm, el sistema es autoportante. Para anchos de impresión mayores, la cámara se apoya en una viga sólida.

Ventajas de utilizar una cámara Nova Compact:

- Rascado eficiente y limpio

gracias al diseño asimétrico de la cámara - Vida útil superior de las raclas

gracias a la baja presión de contacto entre las raclas y el rodillo anilox - Configuración 100% a prueba de fugas

si la cámara está equipada con el plato de retorno opcional - Opción ideal para situaciones de montaje estrechas

gracias al diseño delgado y al sistema de suspensión que ahorra espacio - Cambio rápido y sencillo de raclas y obturadores

- Con el soporte de raclas AkeBoose patentado y sin vibraciones

- Fácil acceso para los trabajos de mantenimiento

La cámara puede extraerse o inclinarse fácilmente en el sistema de suspensión para cambiar las raclas y los obturadores o para su limpieza

La Nova Compact ofrece una excelente relación calidad-precio para aplicaciones de impresión flexográfica de banda estrecha y media. Puede utilizarse con todos los tipos de tinta y es muy ligera, con sólo 5,5 kg por metro.

Si está interesado en un sistema de cámara rentable y fácil de manejar, póngase en contacto con el equipo de AkeBoose.

Día #10 - 25 de junio de 2020 - Desarrollo de obturadores

Presentado por nuestra empresa asociada Agergaard Graphic Supplies GmbH:

Obturadores específicos según la aplicación para un rendimiento óptimo

Lo interesante de los obturadores es que, aunque no parezcan espectaculares, desempeñan un papel crucial para un funcionamiento eficaz y sin problemas del grupo de impresión o de la unidad de revestimiento. Ese pequeño obturador reúne muchos conocimientos sobre el funcionamiento de la respectiva aplicación de impresión, sobre la ciencia de los materiales y sobre los métodos de producción adecuados para hacer un obturador de alto rendimiento.

Nuestro objetivo es proporcionar a nuestros clientes soluciones de sellado que ofrezcan el mejor rendimiento para sus necesidades individuales. El objetivo puede ser prolongar la vida útil del sello en la medida de lo posible; en otros casos, el obturador puede tener que soportar productos químicos especiales o debe ser capaz de hacer frente a una presión variable.

En consecuencia, diseñamos un concepto de obturador adecuado en estrecho diálogo con el cliente, recurriendo a un conjunto de materiales de alta calidad bien probados y a un amplio conocimiento de las mejores prácticas del sector. Nuestros materiales y tecnología de producción se someten a revisiones constantes para identificar el potencial de mejora del rendimiento. En nuestra unidad de pruebas interna, realizamos ensayos de resistencia y comprobamos minuciosamente los nuevos desarrollos antes de que salgan al mercado para ser probados.

Apoyamos a varios fabricantes de prensas con nuestra tecnología de sellado. Asimismo, también es posible realizar desarrollos especiales a menor escala: por ejemplo, hemos diseñado y producido un pequeño lote de obturadores de caucho vulcanizado para una máquina de revestimiento fuera de línea, para la que el fabricante de la máquina ya no ofrecía el suministro de piezas de recambio.

¿Está interesado en un obturador específico para su aplicación de impresión? ¡Póngase en contacto con el equipo de Agergaard!

Día 9 - 24 de junio de 2020 - Sistema de bombeo EPQ 200

Unidad de bombeo de fácil manejo para una óptima circulación de la tinta

El sistema de bombeo EPQ 200 es el complemento perfecto no sólo para los sistemas de cámara de AkeBoose. El sistema cuenta con dos bombas neumáticas de membrana. La bomba de suministro dedicada, que incluye un amortiguador de pulsaciones, transporta la tinta con un flujo constante a la cámara, lo que permite un resultado de impresión uniforme. La bomba de retorno transporta la tinta de vuelta al contenedor de tinta. La ventaja de una bomba de retorno sobre el retorno por gravedad es que la cámara no se sobrepresuriza. Ambas bombas tienen un regulador de velocidad para asegurar que la circulación de la tinta sea equilibrada. Para facilitar la limpieza del sistema de cámara, la bomba de suministro puede invertirse, de modo que la cámara puede evacuarse rápida y completamente a través de la bomba de suministro y la bomba de retorno.

El manejo del sistema EPQ en las operaciones diarias es muy sencillo: los tres modos de funcionamiento de entintado, espera y evacuación se seleccionan con una palanca manual. El sistema de bombeo puede limpiarse simplemente junto con la cámara haciendo circular detergente de lavado en lugar de tinta.

Para el uso de tintas con base de disolvente, el sistema EPQ 200 puede equiparse opcionalmente con bombas con certificación ATEX. En caso de que se utilicen tintas y/o detergentes muy agresivos, el sistema también puede equiparse con una válvula de retención y un diafragma extra robustos y resistentes al desgaste.

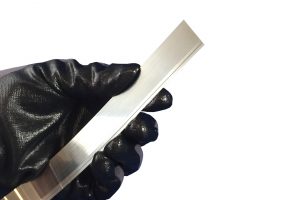

Día 8 - 23 de junio de 2020 - Raclas de plástico

Presentado por nuestra empresa asociada Agergaard Graphic Supplies GmbH:

Aunque tradicionalmente las raclas de acero han sido la primera opción en la impresión flexográfica, las raclas de plástico son cada vez más populares. ¿Por qué?

- Las raclas de plástico están libres de corrosión según su naturaleza.

Pueden utilizarse para todos los tipos de tinta. Esto facilita el mantenimiento de las existencias y las operaciones diarias, ya que los operarios no tienen que poner diferentes materiales de raclas para los distintos tipos de tinta

- El plástico es extremadamente resistente al desgaste.

Con el aumento de la velocidad de impresión y la necesidad de eficiencia para seguir siendo competitivos, la vida útil de las raclas es un factor muy importante. Las cuchillas de plástico tienen mejores propiedades antifricción hacia el rodillo anilox que las opciones de acero de larga duración como, por ejemplo, las cuchillas de acero con revestimiento cerámico, lo que también es beneficioso para la vida útil del rodillo anilox.

- Las raclas de plástico son más seguras de manejar.

Las raclas de acero usadas están muy afiladas y ya han causado muchas lesiones en la sala de impresión. Especialmente en las aplicaciones de banda ancha, el manejo de las raclas es más delicado. Las raclas de plástico no desarrollan bordes tan afilados como las de acero, por lo que es beneficioso para la seguridad en el trabajo utilizar raclas de plástico.

Las raclas de plástico son una opción ideal para muchas aplicaciones:

En general, las raclas de plástico son perfectas para aplicaciones de impresión con imágenes de calidad simple o media.

- Impresión de cartón ondulado

- Impresión en línea

- Impresión o recubrimiento de toda la superficie

- Para utilizar como raclas de contención en cualquier prensa

Agergaard ofrece una gama de raclas de plástico diferentes. Nuestra serie polyBLADE incluye materiales como el poliéster y el UHMW, y nuestra serie fiberBLADE son raclas reforzadas con fibra. Dado que producimos las raclas en nuestra propia empresa en función de los pedidos, podemos satisfacer requisitos individuales, como los distintos ángulos de bisel, con plazos de entrega cortos.

Al mismo tiempo, nos esforzamos por seguir desarrollando nuestros productos. Por ejemplo, estamos estudiando nuevas características de las puntas de las raclas y fórmulas de los materiales para adaptarnos mejor a las necesidades de la impresión de alta resolución en medios tonos. Los prototipos tienen que pasar estrictas pruebas en nuestra unidad de ensayos interna antes de pasar a las pruebas beta en la prensa.

Día 7 - 22 de junio de 2020 - Porta-raclas para huecograbado

Rascado de precisión con costes de funcionamiento reducidos

Las raclas son el corazón del proceso de impresión en huecograbado. Elimina el exceso de tinta directamente del cilindro de impresión, desde donde la tinta se transfiere al sustrato. Tradicionalmente, se requiere una raclas de 40 mm o más con un perfil laminar para lograr la precisión necesaria en la dosificación de la tinta. Teniendo en cuenta una velocidad de impresión típica de 15 m por segundo, una anchura de impresión que suele ser superior a un metro y, con frecuencia, 10 platos de impresión, el consumo de raclas representa una parte considerable de los gastos de funcionamiento.

Los sistemas de soporte de raclas patentados por AkeBoose ofrecen la posibilidad de reducir significativamente los costes de las raclas sin comprometer la calidad de la impresión. El porta-racla se integra en el sistema de fijación de las cuchillas existente en la máquina de huecograbado, por lo que no es necesario tomar medidas de conversión técnica. El sistema de porta-raclas cuenta con una racla de trabajo muy fina de entre 0,065 mm y 0,152 mm de grosor para adaptarse a diferentes grados de calidad de impresión. La estabilidad necesaria para soportar la presión de contacto contra el cilindro se consigue con una racla de apoyo. Sólo la económica racla de 10 mm de anchura debe cambiarse regularmente, mientras que ofrece hasta un 50% más de vida útil que las raclas de huecograbado "normales".

Además del conocido y consolidado sistema de soporte de raclas, AkeBoose también ha inventado el soporte de raclas NewEdge, sin vibraciones, en el que las raclas se pueden fijar perfectamente rectas sin necesidad de herramientas y que es muy fácil de limpiar.

La sensibilidad y la rectitud únicas del sistema de soporte de raclas de AkeBoose reducen la presión de las raclas, lo que se traduce en menos cambios de raclas, menos tiempo de inactividad y una vida útil del cilindro sustancialmente prolongada.

¿Desea reducir los costes y obtener resultados de impresión de alta calidad? Entonces, póngase en contacto con el equipo de AkeBoose.

Día 6 - 21 de junio de 2020 - Aumento del rendimiento con obturadores y raclas personalizados

Presentado por nuestra empresa asociada Agergaard Graphic Supplies GmbH:

Más productividad y menos limpieza

La finalidad de los obturadores es sellar los extremos exteriores del sistema de cámara de entintado en un cuerpo de impresión o unidad de recubrimiento. Para una función de sellado óptima y una larga vida útil, es importante adaptar la forma del sello a la geometría de la cámara y el material del sello a los parámetros de impresión, como el tipo de tinta, la velocidad de impresión, el sustrato, etc.

Los obturadores de Agergaard, que se comercializan bajo el nombre de coatSEAL, se fabrican con materiales de alto rendimiento, como espumas y fieltros técnicos, así como con tipos de caucho y plástico resistentes al desgaste. La gama de obturadores comprende más de 4000 diseños diferentes, que cubren un gran número de marcas y modelos de máquinas de impresión. También es posible realizar desarrollos especiales, ya que contamos con un departamento interno de I+D y un sistema de producción flexible.

Las raclas limpian el exceso de tinta del rodillo anilox que transfiere la tinta a la plancha de impresión. Para garantizar que la tinta se transfiere de manera uniforme y consistente, el material y el diseño de las raclas deben ajustarse a la aplicación de impresión correspondiente.

La gama de raclas de Agergaard incluye acero de alta calidad y materiales plásticos resistentes al desgaste. Los tipos de acero, comercializados bajo el nombre de steelBLADE, incluyen acero al carbono, acero inoxidable y acero para herramientas, que pueden recibir un tratamiento superficial adicional para aumentar la vida útil y las propiedades antifricción de las raclas. Las raclas de plástico, comercializadas con el nombre de polyBLADE y fiberBLADE, se utilizan a menudo en la producción de cartón ondulado o tisú. Debido a la flexibilidad del material, las raclas de plástico también son ideales para su uso como raclas de contención a lo largo de la cámara de tinta.

La ecuación es fácil: obturadores + raclas específicas para la aplicación = más rendimiento de impresión gracias a la reducción de las necesidades de servicio

Vídeo: Aumento del rendimiento de su máquina de impresión con obturadores y raclas personalizados

By loading the video, you agree to YouTube's privacy policy.

Learn more

Día 5 - 20 de junio de 2020 - Cámara de entintado NOVA XLS

Excelencia en el entintado con Nova XLS

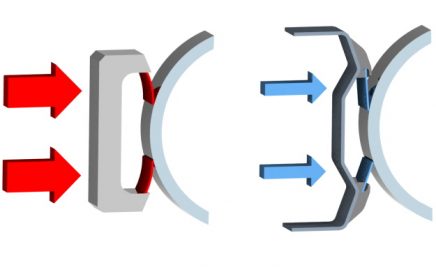

El diseño asimétrico de la cámara, en combinación con el raspado a baja presión, es uno de los secretos para conseguir la mayor productividad y economía posibles en la prensa. Una vida útil mucho más larga de las raclas, la eliminación del "back-doctoring" y de rayaduras son ventajas inmediatas.

Los ángulos optimizados de las raclas, tanto de trabajo como de sellado, eliminan los problemas de rascado y salpicaduras de tinta, reduciendo considerablemente las pérdidas de tinta y los tiempos de inactividad para la limpieza. El principio de rascado a baja presión reduce considerablemente el desgaste de las raclas y de los obturadores.

La posición de bloqueo mecánico de la cámara también permite el uso de raclas más finas y con bordes redondeados, lo que da como resultado unos gastos de funcionamiento muy bajos, incluso a alta velocidad de impresión en envases flexibles.

El sistema de fijación de las raclas, patentado y fácil de usar, no requiere herramientas especiales, palancas, aire comprimido ni mantenimiento especial. Sólo una hendidura de raclas abierta, de fácil acceso, para mantenerla limpia.

Las ventajas del sistema Nova XLS se resumen brevemente:

- Tecnología de acero inoxidable resistente a la corrosión

más rígida que las cámaras de fibra de carbono - Más ligera que las cámaras de fibra de carbono

con sólo 6 - 8 kg por metro - No hay "back-doctoring" ni salpicaduras de tinta

gracias a los ángulos optimizados de las raclas - Opciones de integración versátiles

para adaptarse a diámetros de rodillos anilox de 104 a 312 mm - Mayor duración de las raclas

gracias al rascado de baja presión - Cambio rápido de raclas

con el sistema patentado de fijación sin vibraciones y sin herramientas - Fácil limpieza

gracias al suave diseño interior

Día 4 - 19 de junio de 2020 - Raclas anti-salpicaduras para impresión UV

Presentado por nuestra empresa asociada Agergaard Graphic Supplies GmbH:

Superación de los problemas de salpicaduras de tinta con raclas optimizadas

Un envase de producto atractivo siempre ha desempeñado un papel importante en el proceso de decisión de compra. Con los avances tecnológicos también aumenta la demanda de imágenes de impresión de alta definición para llamar la atención del consumidor. Las tintas UV son un tipo de tinta muy popular en la impresión de envases y etiquetas, entre otras razones porque se secan rápidamente, lo que permite altas velocidades de impresión, y porque los resultados de la impresión pueden reproducirse perfectamente con más facilidad que con otros tipos de tinta.

Sin embargo, hay un fenómeno con las tintas UV que sigue causando problemas a los impresores: La salpicadura de tinta. No sólo ensucia la máquina, sino que también aparece en la web en forma de gotas muy finas que aparecen en la imagen impresa. Se ha investigado mucho para resolver este problema. Se puede optimizar una serie de parámetros del proceso para evitar las salpicaduras de tinta, por ejemplo, un grabado anilox diferente, el control de la temperatura de la tinta y una mejor configuración de las raclas.

En lo que respecta a las raclas, nos fijamos en dos aspectos: La geometría de las raclas y el material de las mismas.

Las raclas de acero suelen considerarse la mejor opción para obtener gráficos de alta calidad, ya que tienen una zona de contacto muy fina con el rodillo anilox para limpiar la tinta. Normalmente, el grosor de las raclas es de 0,15 ó 0,20 mm. Cuando se dosifican tintas UV de alta viscosidad, puede ocurrir que las raclas flexibles se doblen demasiado bajo la presión que ejerce la tinta espesa. Como resultado, las raclas se dosifican de forma desigual, permitiendo que se acumulen pequeñas cantidades de tinta en la parte posterior. Este exceso de tinta salpica entonces a la prensa y a la banda debido a la vibración. La vibración empeora con las velocidades de impresión más altas.

Las raclas steelBLADE CAS de Agergaard están especialmente diseñadas para minimizar las salpicaduras de tinta, ya que combinan la rigidez con la flexibilidad. Las raclas tienen un material base más grueso, lo que hace que la raclas sean menos sensibles a las vibraciones. Para asegurar que la fina zona de contacto entre la punta de la racla y el rodillo anilox se mantenga para un rascado de precisión, rectificamos un perfil especial en la punta de la racla.

Otra opción es adoptar un material de raclas de plástico. El plástico tiene una elasticidad de material diferente a la del acero, siendo menos sensible a las vibraciones. Si bien es cierto que hay límites en cuanto al número de líneas del rodillo anilox que se pueden medir con precisión con una raclas de plástico, puede ser una opción interesante para muchas aplicaciones de impresión basadas en la tecnología UV. La serie polyBLADE P de Agergaard es una raclas termoplásticas muy resistentes al desgaste con una punta de raclas biselada.

Día 3 - 18 de junio de 2020 - Unidad de bombeo EPZ

Suministro de tinta sin pulsaciones con control de flujo continuo

Las unidades de bombeo EPZ están compuestas por un contenedor de tinta de acero inoxidable con tapa y una bomba centrífuga con bypass integrado. Los contenedores de tinta están hechos de acero inoxidable de 2 mm, que es estable y fácil de limpiar. El fondo inclinado del contenedor hace que la tinta pueda circular perfectamente incluso con un nivel de llenado bajo. La bomba centrífuga con bypass integrado permite un flujo de tinta continuo de 1 a 25 litros por minuto sin pulsaciones.

La configuración de la unidad de bombeo está diseñada para ofrecer la máxima flexibilidad: con la misma bomba y el mismo bypass se pueden utilizar contenedores de tinta de diferentes tamaños, desde 25 hasta 55 litros.

¿Desea beneficiarse de una unidad de bombeo inteligente y económica? Póngase en contacto con el equipo de AkeBoose para obtener más información.

Día 2 - 17 de junio de 2020 - Obturadores para altas velocidades

Presentado por nuestra empresa asociada Agergaard Graphic Supplies GmbH:

Sellado eficaz de las cámaras durante más tiempo

La tecnología de impresión de alta tecnología actual permite aumentar las velocidades de impresión, a menudo muy por encima de los 600 m/min en la impresión de banda ancha. Tales velocidades de impresión exigen mucho de los obturadores, dado el aumento de la fricción y el calor que evolucionan en el proceso. Agergaard se ha especializado en la producción de obturadores de alto rendimiento durante muchos años y se está centrando mucho en el desarrollo de conceptos de obturadores fiables que mantengan la cámara hermética y ofrezcan una vida útil avanzada incluso en entornos de impresión difíciles.

El camino hacia el éxito requiere tener en cuenta los respectivos parámetros de impresión y elegir un concepto de obturador adecuado. Para la impresión de alta velocidad, recomendamos tres soluciones de sellado con propiedades antifricción mejoradas de la gama de Agergaard:

coatSEAL NW 2.5D para UV

Un obturador de espuma estable con una parte superior del sello biselada y una zona de contacto optimizada entre el obturador y el rodillo anilox, ideal para las tintas UV.

coatSEAL AIR80-PTFE para solventes

Un obturador de espuma de caucho con efecto memoria y una parte superior de obturación recubierta, ideal para las tintas con base de disolvente.

coatSEAL Universal para todas las tintas

Un obturador de goma moldeada extremadamente resistente al desgaste y versátil que se adapta a todos los tipos de tinta y revestimiento.

Día 1 - 16 de junio de 2020 - Cámara de entintado NOVA RS

Los sistemas de cámara AkeBoose Nova RS tienen un depósito de tinta, lo que significa que pueden utilizarse sin una bomba de tinta externa. Sólo se necesita un pequeño volumen de tinta para que el sistema funcione. La delgada geometría de la cámara tiene contornos fluidos, lo que reduce considerablemente los esfuerzos de limpieza. Es casi imposible que la tinta permanezca en la cámara al ser evacuada, ya que la cámara no tiene esquinas ni bordes.

Como todos los sistemas de cámara de AkeBoose, las cámaras RS están equipadas con la fijación de raclas patentada sin herramientas, lo que permite cambiar rápida y fácilmente las raclas y los obturadores y garantiza un ajuste seguro y recto de las raclas en la cámara. El rascado "Kiss Impression" con poca presión de la cámara hacia el rodillo anilox asegura que las raclas limpien la tinta en el rodillo anilox de forma eficaz y uniforme, sin dejar de ser suaves con el revestimiento cerámico del rodillo anilox. Además, el principio de baja presión es beneficioso para la vida útil de las raclas y los obturadores.

Las cámaras Nova RS son ideales para su uso en la impresión de banda estrecha con base UV. Pueden integrarse con los sistemas de suspensión existentes en la máquina de impresión de etiquetas.

Las primeras cámaras Nova RS "plug-and-play" ya se han instalado en imprentas con prensas Nilpeter FA.

¡No podemos esperar a conocerle de nuevo en persona!

Mientras tanto, debemos limitarnos principalmente a la comunicación digital: ¡no dude en ponerse en contacto con nosotros!

Estaremos encantados de programar una videollamada o una llamada telefónica para discutir sus necesidades en detalle.