Highlights of the End-seal Spray System

Better sealing results

Longer end seal lifetime

Less machine downtime and cleaning effort

Clean printing with quick-drying water-borne inks

The End-seal Spray System (ESS) is specially developed for printing with water-borne inks on film. With plastic film being a non-absorbent substrate, these water-borne inks are designed to dry very quickly. This is necessary to meet demands of high printing speeds in modern CI flexo presses.

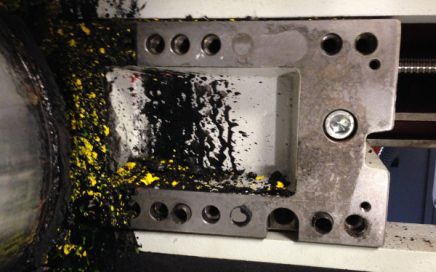

At the same time, the quick-drying characteristics of these water-borne inks pose a challenge in terms of sealing and cleaning the chamber. At the end seal area of the chamber, the anilox roller rotation against the end seal causes frictional heat that increases the evaporation of the ink vehicle, i.e. the water. As a result, ink particles tend to dry up on and around the end seal, which ultimately can destroy the end seal and cause leakage. If not taken care of immediately, these ink leaks can cause heavy soiling of the printing deck which is very difficult and time-consuming to clean.

End seal humidification for better sealing results and longer seal lifetime

The End-seal Spray System finds a remedy for this issue by systematically humidifying the end seal area in a way that avoids ink from drying up without diluting the ink in the cycle.

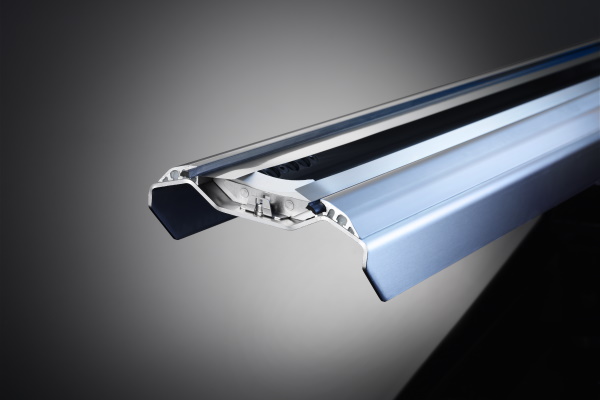

To this end, the end seal area of the NOVA XLS chamber system is built with a double end seal. A special end seal holder is installed in the chamber, featuring two end seals with space in between both. The inner end seal actually limits the ink-carrying area at the end of the engraved screen roller surface; while the outer end seal seals the humidification area.

How the End-seal Spray System works

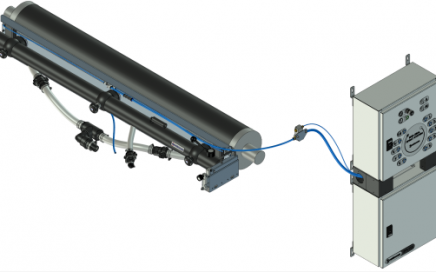

Between the two end seals sits a nozzle that sprays water into the humidification area at pre-programmed intervals, typically for 2-3 seconds per minute. The water spray system has a separate supply and return circuit. The water pump and the control panel are compactly stored in a control cabinet for easy access and maintenance. It only requires water, pressurized air and a power connection to be ready for operation. Between the control unit and the chamber system sits an inline process valve that doses the spray quantity.

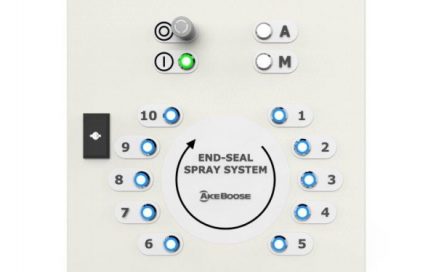

Worry-free printing for up to 10 printing units

On the control panel, up to 10 printing decks can be activated or deactivated for the spray pulse. The duration of the spray as well as the interval between sprays per cycle can be programmed for the automatic mode. It is also possible to manually trigger additional spray pulses sporadically by pressing a designated button.

The End-seal Spray System is an additional option in combination with our NOVA XLS chamber doctor blade system that offers high-precision ink metering without back doctoring, low maintenance requirements as well as easy handling with tool-free end seal and doctor blade changes.

![]()

RELATED TOPICS

![]()

NOVA XLS stainless steel chamber system for medium to wide web printing

Clean design for high precision doctoring at low operating costs. Goodbye back doctoring, hello efficiency! Read more

EPQ 300 ink supply system for easy cleaning

Compact and straightforward ink supply system with integrated cleaning cycle. Read more